|

There are hundreds of manufacturers of pH (or ORP) probes. Some cost as little as $100. The probes that SCT distributes cost more than six times that much. You would have to burn through six or more traditional probes to justify buying just one of ours. Our favorite probes are the ones from Aquametrix, and they go on to explain why.

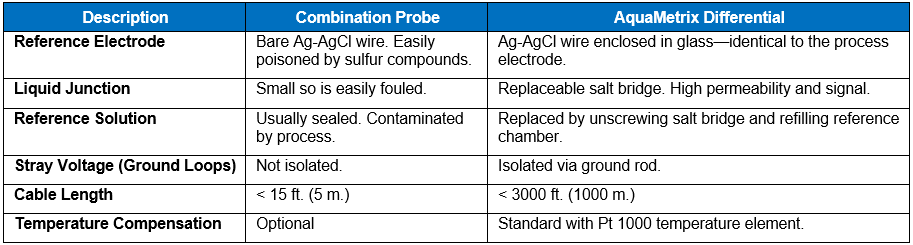

Ever buy a $99 printer only to find that you spend that much every month just for the ink? Then you understand that the initial cost can be very different from the total cost of ownership. So, let’s talk total cost of ownership. Can SCT and Aquametrix really claim that one of their pH probes will outlast six of the other guys? Well…yes. Most pH/ORP probes are combination probes. (They get that confusing name because the reference electrode and process electrode are “combined” into one glass or plastic body. A typical combination probe may last for two years in clean water, but it will be blessed if it lasts 6 months in a moderately challenging environment, like wastewater. That’s a cost of about $200/year. Typically, the things that kills a typical combination pH probe include contamination of the reference solution, poisoning of the reference electrode or plugging of the liquid junction. A differential probe, however, replaces the bare silver wire that serves as a reference electrode with a completely enclosed glass electrode that is identical to the process (measuring) electrode. This means it can’t be poisoned. The liquid junction (the tiny porous structure that allows current to flow from the process to the measuring electrode) is replaced by a big, beefy, replaceable salt bridge. This means that, when the junction gets plugged up, you can just throw it away and screw in a new one. It also means that, when the reference solution becomes contaminated with the process, you can just unscrew the salt bridge, pour out the old solution and add new solution. Remember, that in a combination probe, the reference electrode and the process electrode are “combined” into one complete circuit. So, when a stray voltage from, say, a ground loop, finds its way into the process it messes up the exposed reference electrode (a bare silver wire coated with silver chloride). But a differential probe uses two identical electrodes—both sealed in glass and immersed in a salt solution—and each is connected to a ground rod to make two half-circuits. When a stray voltage creeps into the process it goes straight to the ground rod and is subtracted from both electrodes. See the schematic below. So, no faulty readings. No ground loops. The differential probe has an embedded pre-amplifier. That means instead of being restricted to a 15-foot length cable typical of a combination probe, the cable of one our our partner probes can be 1000 feet or longer. So the decision is yours. Remember one failure can be costly in compliance or system upsets with chemical overuse, and other bad things. One related thing to keep in mind is - how often will a person run out to your site to train your operators, help with problems, fix minor issues? SCT will. You can count on that.  Do you know what a grease interceptor is (commonly known as a grease trap)? How about inspectors who monitor grease traps? If so, then you are probably aware the only way to measure the level of FOG (fats, oils, and grease) is to use a core sampler, like a Sludge Judge or a Dipstick Pro. And you know these devices are incredibly messy, time consuming and prone to failure. Until now. SCT is distributing the first production ready probe that can be inserted into a grease trap and measure the level of FOG in less than a minute. It’s called the AM-FOG probe and it is the first such device that can be carried around like a core sampler but without the mess, the stink and the headaches of a device that fails more often than it works. The AM-FOG probe works by measuring the electrical properties of the surrounding medium. Because it has no moving parts there is nothing to wear out or break down. The AM-FOG communicates via low-energy Bluetooth (BLE) to an Android or iOS app on your cell phone or tablet. It’s incredibly easy to use and will pay for itself in a few weeks when the inspector or hauler is able to triple his or her rate of inspections. Reach out to Joe or David at SCT and learn about this convenient tool of the trade. Customer

Ardnamurchan Estates own and manage a significant proportion of the Ardnamurchan Peninsula on the west coast of Scotland. Activities include tourism, cattle and sheep farming, sport fishing, deer hunting, forestry and distillery. Customer’s needs Pot Ale is a waste product from the whisky distilling process and is the residue left in the bottom of the copper still after the distillation process is complete. The Clients needs to convert the Pot Ale to Pot Ale Syrup and then use this as a feed for their cattle farm. The Solution provided Two units: EVALED RV F 15 and a EVALED PC R 2. EVALED RV F is a range of mechanical vapor recompression evaporators designed to achieve the most reliable heat exchange with the minimum fouling and scaling. EVALED PC R is a range of heat pump vacuum evaporators designed to treat liquids with a high content of dissolved solids at low temperature and able to manage a high level of fouling and scaling phenomena (viscous liquids, sediment presence). The Solution achieved The solution achieved the production of a Good quality Pot Ale Syrup thanks to a low energy solution and Perfect size of the equipment, suitable for the relatively small quantities of Pot Ale processed daily (traditionally, Pot Ale Syrup evaporators have only been installed in larger distilleries with a higher daily production of Pot Ale). At the same time the solution achieved an effective and automated cleaning system for the evaporators. PFOA & PFOS have been overlooked as an environmental contaminant until recently. These compounds have been widely used in firefighting foams and consumer products for decades. Similarly to PCBs, PFOA & PFOS spread easily, do not break down, and can remain in water plumes indefinitely. With new regulations requiring treatment down to the parts per trillion range, effective treatment will be a growing concern in upcoming years.

H2K Technologies has treatment solutions Specific treatment approach will vary with concentration and individual site characteristics, but removal can generally be handled by a combination of activated carbon, ionic resin, and solids filtration. While carbon is often the most cost effective option, ionic resins are selective for PFOA/PFOS and can provide better removal when other organic loading is present. Our experienced team of engineers can review sampling data, model treatment performance, recommend treatment approach and estimate the media lifespan for your project. Our expertise will help you provide a custom turnkey solution to provide effective results for the lifespan of a project. Whenever you're looking for new or used wastewater and remediation equipment sales and rentals, call or email Joe or David to find the best solution for your project - an engineer will contact you to evaluate your application. Water is our business and we manufacture a full product line to assist with your next project.  EVALED® Evaporators for pharmaceutical waste water.CASE STUDY Capsule printing, pharmaceutical waste water. EVALED PC F / Heat pump vacuum evaporators The Client is a science-led global healthcare company, with 3 global businesses that research, develop and manufacture innovative pharmaceutical medicines, vaccines and consumer healthcare products. In their Polish premises, they use a unique technology to print directly on capsules with a low energy laser. The Client aims to reduce the residue to incinerate and the relevant costs. To achieve this goal, the solution provided consists of a PC F 4 evaporator with a distillate production capacity of 4 m3/day and a footprint of 3.2 m2. EVALED PC F is a line of heat pump vacuum evaporators designed to treat liquids with a high content of dissolved solids while minimizing the fouling and scaling phenomena with low temperature evaporation. To find out the results achieved click here Contact Us Main advantages of the EVALED PC F Evaporators

Discover more about EVALED® PC F evaporators |

SCT BlogTopics and Announcements. Archives

March 2022

Categories |

Proudly powered by Weebly

RSS Feed

RSS Feed